Enhancing Safety Standards with Advanced Process Control Systems

Understanding Advanced Process Control Systems

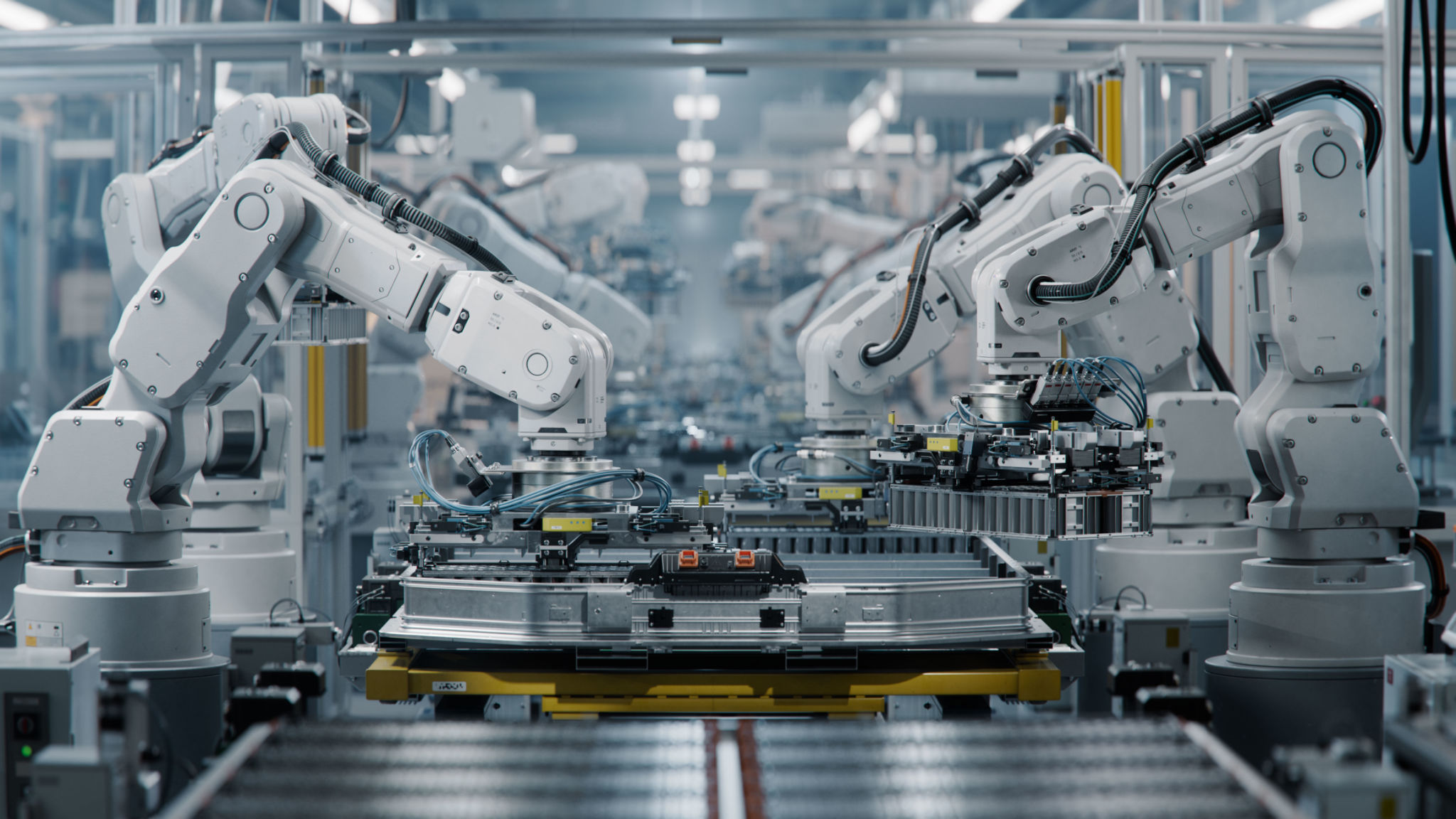

In today's rapidly evolving industrial landscape, ensuring safety standards is paramount. One of the most effective ways to enhance these standards is through the implementation of Advanced Process Control (APC) systems. These systems use sophisticated algorithms and real-time data analysis to optimize industrial processes, ensuring both efficiency and safety.

Advanced Process Control systems are designed to manage complex operations by predicting process behaviors and adjusting control variables accordingly. This proactive approach not only enhances operational efficiency but also significantly reduces the risk of safety incidents.

Key Components of APC Systems

APC systems consist of several key components, each playing a critical role in ensuring safety. These include:

- Data Acquisition: Collecting real-time data from various sensors and inputs across the facility.

- Modeling and Simulation: Creating predictive models to simulate different scenarios and outcomes.

- Control Strategies: Implementing strategies that adjust process variables to maintain optimal conditions.

By integrating these components, APC systems provide a comprehensive framework for maintaining safety and efficiency in industrial environments.

The Role of Predictive Analytics

Predictive analytics is a cornerstone of Advanced Process Control systems. By analyzing historical and real-time data, APC systems can anticipate potential issues before they arise, allowing for preemptive measures to be taken. This capability is crucial in preventing accidents and ensuring smooth operations.

For instance, if a particular process parameter begins to deviate from its normal range, the APC system can automatically adjust other variables to compensate, thereby avoiding potential hazards. This level of automation and foresight is a significant advancement in industrial safety.

Benefits of Implementing APC Systems

The advantages of adopting Advanced Process Control systems are manifold. Not only do they enhance safety, but they also improve operational efficiency and reduce costs. Here are some key benefits:

- Improved Safety: By predicting potential issues and taking corrective actions, APC systems significantly reduce the risk of accidents.

- Increased Efficiency: Optimized processes lead to better resource utilization and reduced downtime.

- Cost Savings: Efficient operations and reduced safety incidents translate to lower operational costs.

Challenges in Implementing APC Systems

Despite the numerous benefits, implementing APC systems can be challenging. The complexity of integrating these systems with existing infrastructure requires significant expertise and investment. Additionally, there may be resistance to change from personnel accustomed to traditional methods.

To overcome these challenges, companies must invest in training and support for their staff, ensuring a smooth transition to advanced control systems. Furthermore, collaboration with experienced vendors can facilitate successful implementation and integration.

The Future of Safety in Industrial Processes

The continuous evolution of technology promises even greater advancements in safety standards through Advanced Process Control systems. With the integration of artificial intelligence and machine learning, future APC systems will offer even more precise and autonomous control capabilities.

As industries strive to meet ever-increasing safety standards, the role of APC systems will become increasingly vital. By embracing these technologies, companies can not only ensure compliance but also protect their most valuable assets: their people and facilities.