The Ultimate Guide to Industrial Process Control: Enhancing Efficiency and Safety

Understanding Industrial Process Control

Industrial process control is a vital component in modern manufacturing and production environments. It involves the use of technology and systems to manage and regulate processes, ensuring they operate within set parameters. This not only enhances efficiency but also ensures the safety of operations. By implementing effective process control strategies, industries can optimize their resources and minimize risks associated with industrial processes.

Key Components of Process Control Systems

A robust process control system typically consists of sensors, controllers, and actuators. Sensors are responsible for collecting data from various points in the process, such as temperature, pressure, or flow rate. Controllers process this data to make real-time decisions and adjustments. Finally, actuators carry out these adjustments by altering conditions or machinery settings to align with desired outcomes.

Additionally, software plays a critical role in process control by analyzing data trends, predicting potential issues, and optimizing the use of resources. Advanced software solutions can even automate decision-making processes, allowing for more efficient and reliable operations.

Enhancing Efficiency Through Automation

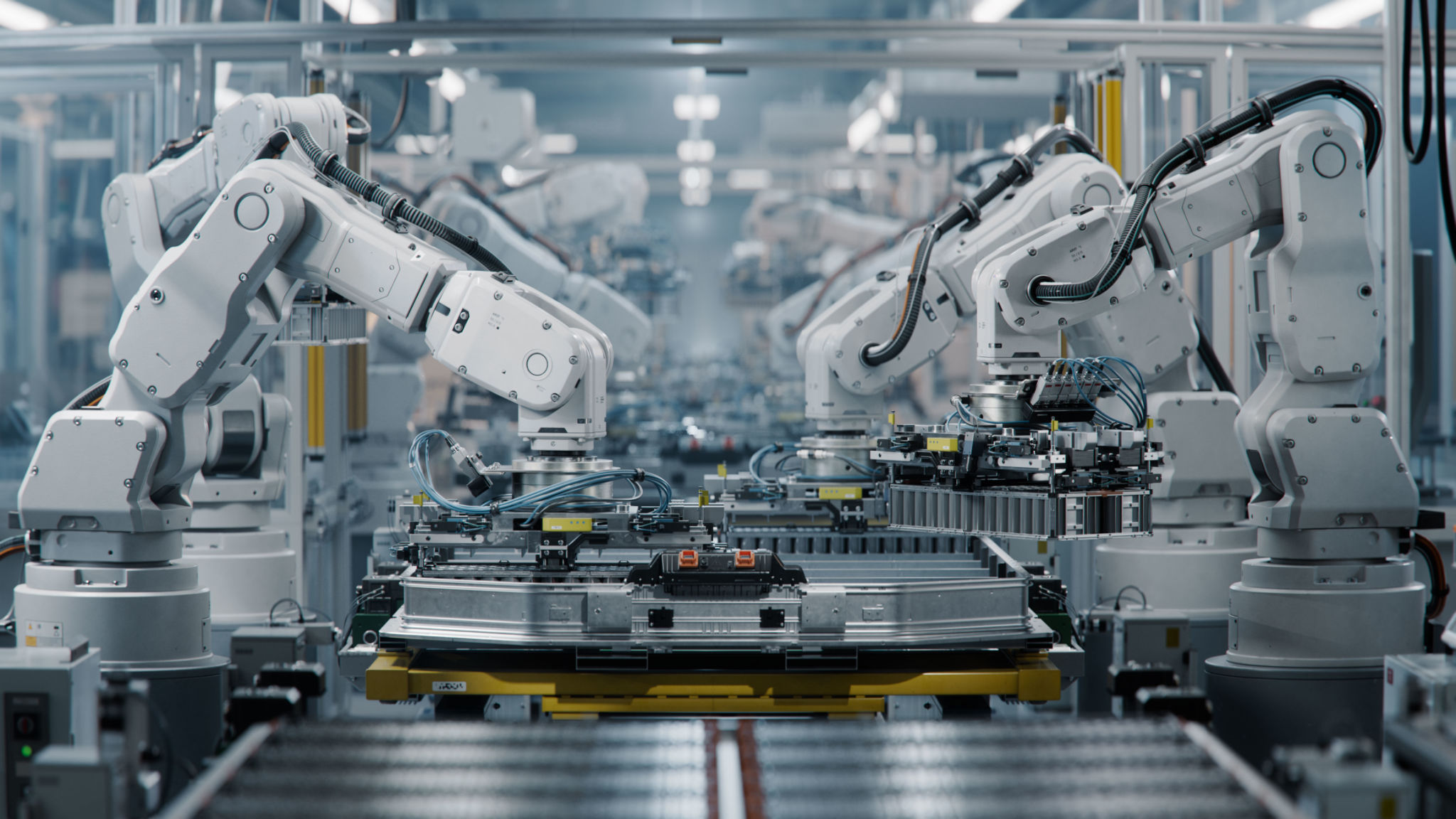

Automation is at the heart of improving efficiency in industrial process control. By automating repetitive tasks and processes, companies can reduce human error, increase production speed, and ensure consistent quality. Automated systems can also operate continuously without fatigue, leading to higher output levels over time.

With automation, industries can also gather more accurate data and insights into their processes. This data can be used to further refine operations, identify bottlenecks, and implement changes that lead to optimal performance. As a result, businesses can achieve higher productivity and profitability.

Ensuring Safety in Process Control

Safety is a primary concern in industrial environments, and effective process control systems play a crucial role in maintaining it. By continuously monitoring operations and promptly addressing deviations from normal parameters, these systems help prevent accidents and ensure the well-being of workers.

Moreover, implementing safety protocols within process control systems can mitigate risks associated with hazardous materials or high-pressure environments. Investing in reliable safety mechanisms not only protects personnel but also safeguards equipment from damage.

The Role of Data Analytics

Data analytics has become increasingly important in industrial process control. By leveraging large volumes of data collected from various sources, industries can gain deeper insights into their operations. Data analytics enables predictive maintenance, which helps in anticipating equipment failures before they occur, thus minimizing downtime.

Furthermore, data-driven decision-making allows industries to optimize resource allocation and improve overall efficiency. Advanced analytics tools can identify trends that human operators might miss, providing a competitive edge in rapidly changing markets.

Implementing an Effective Process Control Strategy

To implement an effective process control strategy, industries should start by assessing their current systems and identifying areas for improvement. This involves evaluating existing technology, understanding operational goals, and aligning them with available resources.

Developing a comprehensive strategy may include upgrading equipment, adopting new technologies, or retraining staff to handle advanced systems. Collaboration between various departments is crucial to ensure that the strategy is well-rounded and addresses all aspects of the production cycle.

The Future of Industrial Process Control

The future of industrial process control lies in embracing new technologies such as artificial intelligence (AI) and the Internet of Things (IoT). These innovations will further enhance efficiency and safety by providing real-time data analysis and adaptive control mechanisms.

As industries continue to evolve, staying ahead of technological advancements will be key to maintaining competitiveness. By integrating cutting-edge solutions into process control systems, businesses can achieve unprecedented levels of precision and reliability in their operations.